CI Flexo Printing Machines: Enhancing Flexibility and Efficiency in Packaging Production

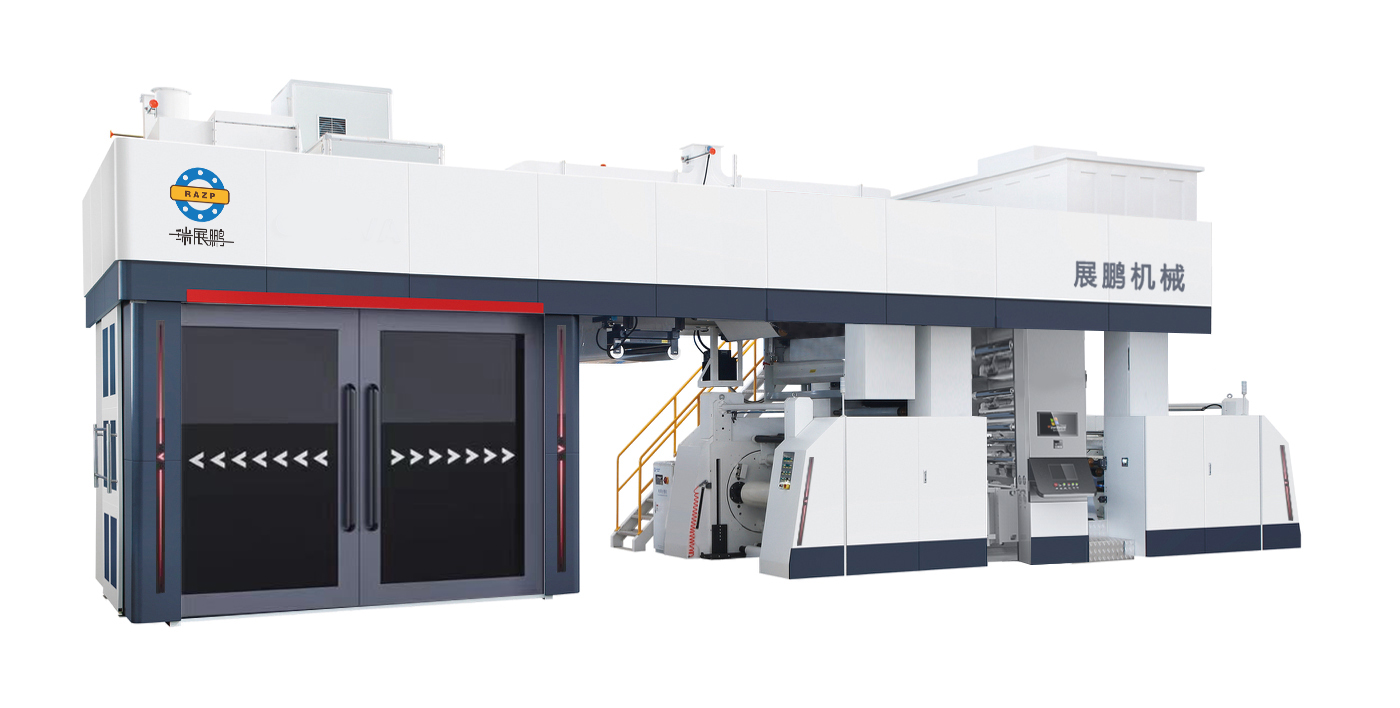

CI flexo printing machines are continuing to play a crucial role in the packaging industry by offering enhanced flexibility and efficient printing capabilities for a variety of substrates. These machines, designed with a central impression cylinder, are primarily used for producing high-quality prints on flexible materials like films, labels, and flexible packaging. CI flexo printing machines are increasingly being recognized for their ability to deliver consistent results across different materials and printing applications.

One of the key advantages of CI flexo printing machines is their suitability for high-volume production runs. By employing a central impression drum, these machines ensure consistent registration and superior print quality, even during long print runs. This feature is particularly beneficial in industries that require mass production of packaging, such as food and beverage, pharmaceuticals, and consumer goods. The ability to maintain precise print quality over extended periods contributes to cost-effective manufacturing, making these machines popular in large-scale production environments.

CI flexo printing machines are highly adaptable to various substrates, ranging from lightweight films to thicker, more rigid materials. The central impression cylinder design allows for stable and uniform printing, which is crucial for achieving high-quality results on flexible and challenging materials. This adaptability makes them suitable for a wide range of packaging products, from simple labels to complex, multi-layered packaging designs. Their flexibility in handling different materials further expands their appeal to manufacturers with diverse production needs.

In recent years, CI flexo printing technology has seen several advancements aimed at improving efficiency and minimizing waste. Modern machines incorporate features such as automated registration control, enhanced drying systems, and better ink management. These innovations help reduce setup times and material waste, making the printing process more streamlined and sustainable. Additionally, improvements in ink formulations, including water-based and UV-cured inks, have made it easier for CI flexo printers to meet evolving environmental standards.

Another significant benefit of CI flexo printing machines is their ease of use and maintenance. Many newer models are equipped with advanced control systems that simplify operation, allowing for quicker setup and less downtime between print runs. This ease of operation reduces the learning curve for new operators and improves overall production efficiency. Moreover, the machine's design makes it relatively straightforward to clean and maintain, ensuring that production schedules are not interrupted by lengthy maintenance procedures.

CI flexo printing machines are also valued for their ability to produce vibrant and detailed prints, making them ideal for applications that require high visual appeal, such as food packaging and branded labels. The combination of excellent print quality and versatility in handling different substrates makes CI flexo machines suitable for both short and long runs, offering manufacturers the flexibility to meet varying market demands.

Manufacturers are increasingly focused on reducing their environmental footprint by incorporating energy-efficient features and using sustainable ink and material options. CI flexo printers are aligning with these trends by offering solutions that support eco-friendly production practices while still delivering high-quality prints.

In conclusion, CI flexo printing machines offer a reliable and efficient solution for high-quality packaging production. Their flexibility in handling various substrates, ability to produce consistent results in high-volume runs, and advanced technological features make them a popular choice for manufacturers across different industries.

English

English 中文简体

中文简体 عربى

عربى

Contact Us