Parallel Shaft Gear Box Motor in Industrial Automation

The Parallel Shaft Gear Box Motor has been attracting attention in industrial automation and mechanical systems. In this design, the output shaft is aligned parallel to the motor shaft, which allows efficient torque transfer and precise speed reduction. This configuration is widely applied in conveyors, packaging machinery, and material handling systems where consistent performance is required.

The global market for parallel shaft gear motors has been growing steadily, driven by demand in the manufacturing and logistics sectors. These motors provide reliable torque at low speeds, and their straightforward gear arrangement makes maintenance easier. Helical and spur gears are commonly used, offering different advantages in noise control and load capacity.

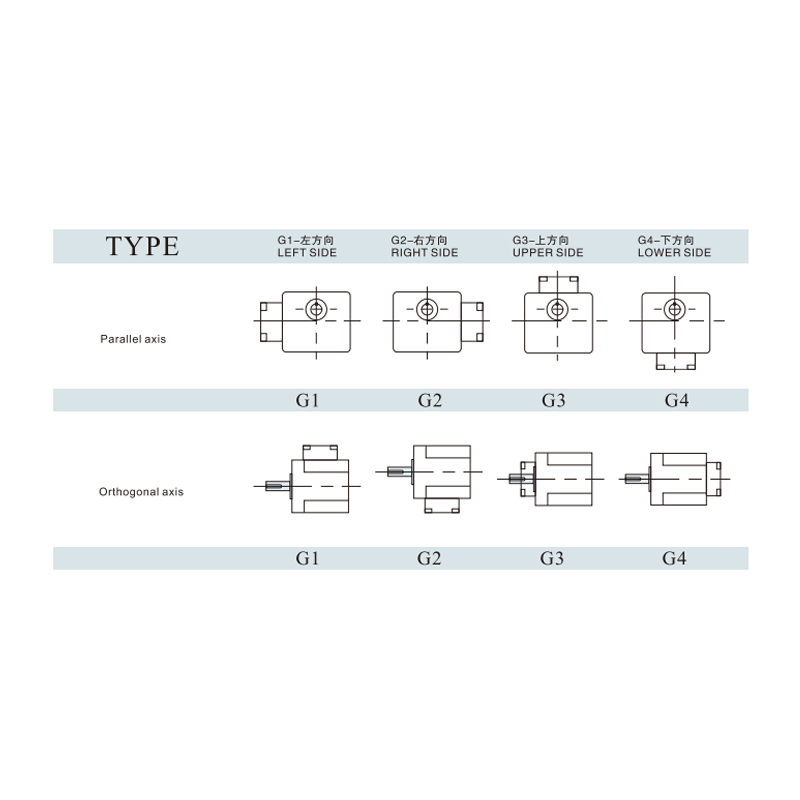

Engineers highlight that parallel shaft gear motors are suited to continuous operation. Their design reduces vibration and mechanical stress, which contributes to longer service life and stable output. The motors also support a variety of mounting configurations and gear ratios, allowing them to adapt to diverse industrial layouts.

In material handling facilities, parallel shaft gear motors are used in automated guided vehicles (AGVs) and conveyor systems where precision and uptime are important. The motors can deliver smooth motion while handling moderate to high torque, which helps reduce interruptions in production processes.

Modern manufacturing emphasizes energy efficiency. Parallel shaft motors with optimized gearing can improve energy performance without requiring significant redesigns of existing machinery. Additionally, their compact construction allows integration into systems with space constraints, providing both operational flexibility and mechanical reliability.

Some advanced models include lubrication systems designed for longer service intervals, as well as modular housings that allow faster replacement or integration with larger machines. Companies installing these motors often pair them with variable frequency drives or programmable controllers to improve speed regulation and adapt torque to process requirements.

Applications also extend to agriculture and food processing, where machinery needs smooth operation without frequent maintenance. For example, motors on mixers, feeders, and packaging conveyors benefit from the torque consistency and alignment offered by parallel shaft designs. Their relatively simple gear arrangement reduces the likelihood of misalignment under heavy loads, which can be critical in continuous production lines.

In addition, some factories have integrated these motors into automated storage and retrieval systems, where consistent motion and low vibration are important to protect delicate products. Parallel shaft gear motors also support modular machinery setups, allowing manufacturers to scale production lines with minimal mechanical adjustments.

In summary, the Parallel Shaft Gear Box Motor continues to support industrial operations by offering alignment flexibility, reliable torque, and adaptable performance. Its use across multiple sectors highlights its role in systems that require precise and durable mechanical transmission, and its combination of efficiency, adaptability, and maintainability makes it a practical choice for modern industrial environments.

Frequently Asked Questions (FAQ)

Q: What is a parallel shaft gear motor?

A: It is a motor with a gear reducer in which the input and output shafts are parallel, allowing direct torque transmission.

Q: Where is it commonly used?

A: Applications include conveyors, packaging machines, and material handling systems.

Q: What are its advantages?

A: Reliable torque at low speeds, lower vibration, and flexible mounting options.

Q: Can it operate continuously?

A: Yes, the design supports extended operation in industrial environments.

Q: Are there customizable options?

A: Yes, manufacturers offer different gear ratios and mounting styles for specific needs.

English

English 中文简体

中文简体 عربى

عربى

Contact Us