Cold Resistant Gear Motor for Harsh Environments

Introduction

A cold resistant gear motor is designed for industries and applications that demand reliable performance in freezing temperatures. While standard gear motors may face difficulties in sub-zero conditions, models engineered for cold resistance help ensure steady operation. Their ability to support machinery in challenging outdoor and controlled environments makes them increasingly important across several sectors.

What Makes a Cold Resistant Gear Motor Different

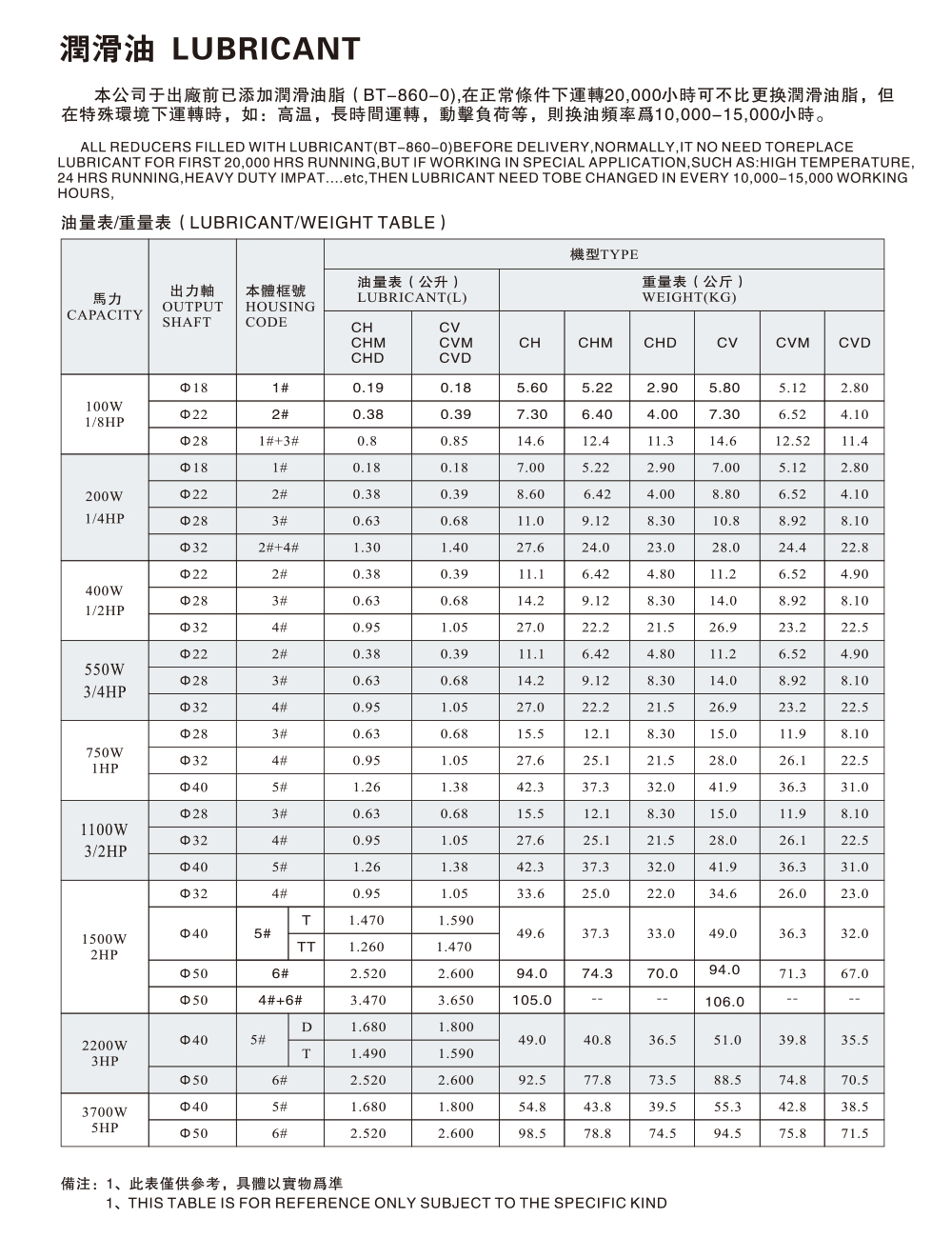

A gear motor integrates an electric motor with a gear system to regulate torque and speed. Cold resistant models incorporate durable materials, specialized lubricants, and sealed housings that allow them to keep working when exposed to snow, ice, or extremely low temperatures. These improvements provide consistent functionality and help minimize downtime in critical operations.

Key Environments for Application

- Arctic and Polar Stations

Research facilities in polar regions require dependable machines to carry out daily tasks and long-term scientific projects. Cold resistant gear motors are used in drilling systems, lifting devices, and transport equipment, making it possible for operations to continue under extreme weather conditions.

- Mining in Cold Regions

Mining sites located in northern territories face continuous exposure to freezing climates. Equipment powered by cold resistant gear motors supports conveyor belts, crushers, and excavation systems. Their resilience keeps the flow of materials stable in underground or open-pit mining projects, even during severe winter seasons.

- Renewable Energy in Cold Climates

Wind farms in snowy or icy regions depend on motors that remain efficient despite low temperatures. Cold resistant gear motors help adjust turbine blades, operate control panels, and maintain supporting systems. Their durability ensures that renewable energy facilities remain functional even during long periods of frost.

- Cold Storage and Refrigerated Logistics

In addition to natural climates, artificial cold environments such as refrigerated warehouses require reliable motion systems. Cold resistant gear motors drive conveyors, lifts, and packaging machinery, maintaining safe handling of perishable products. They contribute to logistics systems where consistent temperature control is necessary for product quality.

- Military and Emergency Applications

Vehicles and field equipment used in remote cold areas often rely on gear motors designed for freezing temperatures. From rescue missions to defense tasks, cold resistant gear motors support mobility, communications equipment, and portable power units that must operate regardless of severe weather.

- Design Considerations

Several factors ensure that these motors deliver strong performance in demanding environments:

Material Selection: Metals and polymers used in construction resist cracking and brittleness under low temperatures.

Lubrication Systems: Low-temperature lubricants keep friction levels reduced and allow gears to rotate smoothly.

Sealed Housings: Protective casings prevent ice, snow, and moisture from reaching sensitive motor components.

Energy Balance: Careful design allows for efficient power use without unnecessary waste, ensuring consistent operation in cold conditions.

Maintenance Requirements: Many models are built for easier inspection and servicing, which supports long-term reliability.

Expanding Industrial Use

The application of cold resistant gear motors is no longer limited to traditional industries. Agricultural equipment in northern regions, automated port systems, and advanced manufacturing sites also benefit from this technology. Each of these areas requires dependable motion solutions that function in environments where ordinary motors would struggle. Emerging integration with digital monitoring systems is expected to improve efficiency, giving operators real-time insight into motor performance and preventive care.

Conclusion

The importance of cold resistant gear motors continues to rise across multiple industries. Providing reliable motion in low-temperature environments, they ensure continuity in mining, research, logistics, renewable energy, and emergency operations.

English

English 中文简体

中文简体 عربى

عربى

Contact Us