High Power Gear Motor Applications Expand

The demand for High Power Gear Motor solutions continues to grow across manufacturing, logistics, and engineering environments as companies seek stable and adaptable mechanical power systems. Many organizations now evaluate not only torque output but also installation space, energy usage, and long-term operational reliability. This shift encourages decision-makers to consider how gear motor configurations can influence performance, cost, and equipment lifespan.

Industry discussions frequently highlight several questions. How can torque and speed be balanced more effectively? Which gear ratios support specific workloads? And how can buyers evaluate the trade-offs between direct-drive and gear-reduction systems? These questions shape procurement strategies in sectors such as conveyors, heavy-duty processing equipment, automated packaging, and continuous-operation machinery.

Advantages and Benefits of High Power Gear Motors

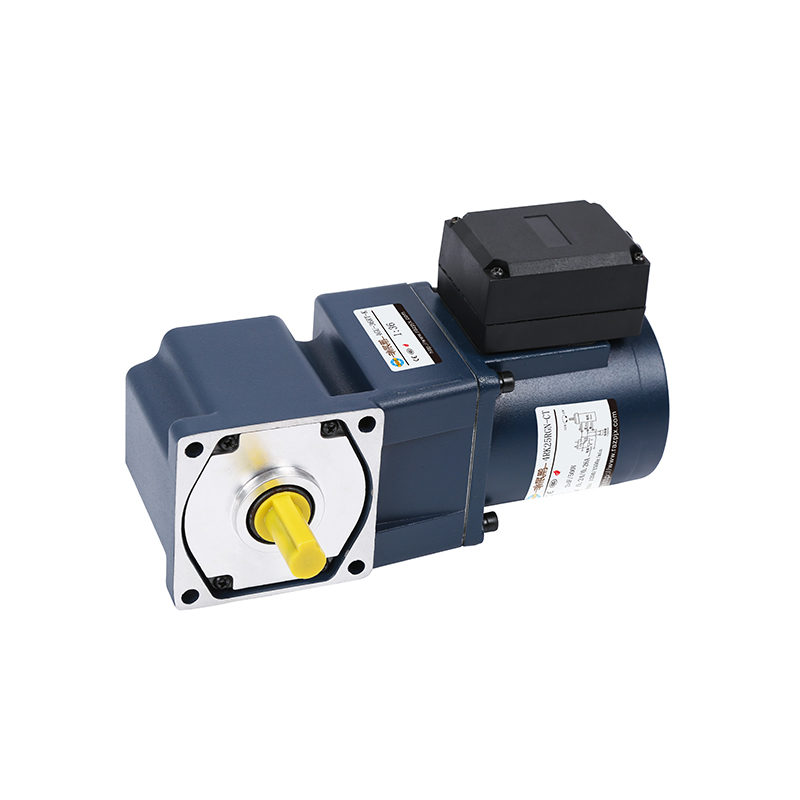

One of the most reported strengths of High Power Gear Motor units is the ability to deliver high torque output suitable for heavy loads and continuous-duty applications. This performance characteristic supports equipment used in warehouses, material handling, lifting systems, mixers, and industrial production lines.

A second advantage is compact size. Many machines face installation limits, prompting engineers to select gear motors that provide strong output while fitting into restricted mechanical spaces. These compact configurations help simplify equipment layout and reduce redesign requirements.

Energy usage considerations also play a role. When the motor and gearbox are properly matched, energy consumption can be lowered due to improved efficiency across the power transmission system. This becomes important in facilities with long operating hours or energy-management requirements.

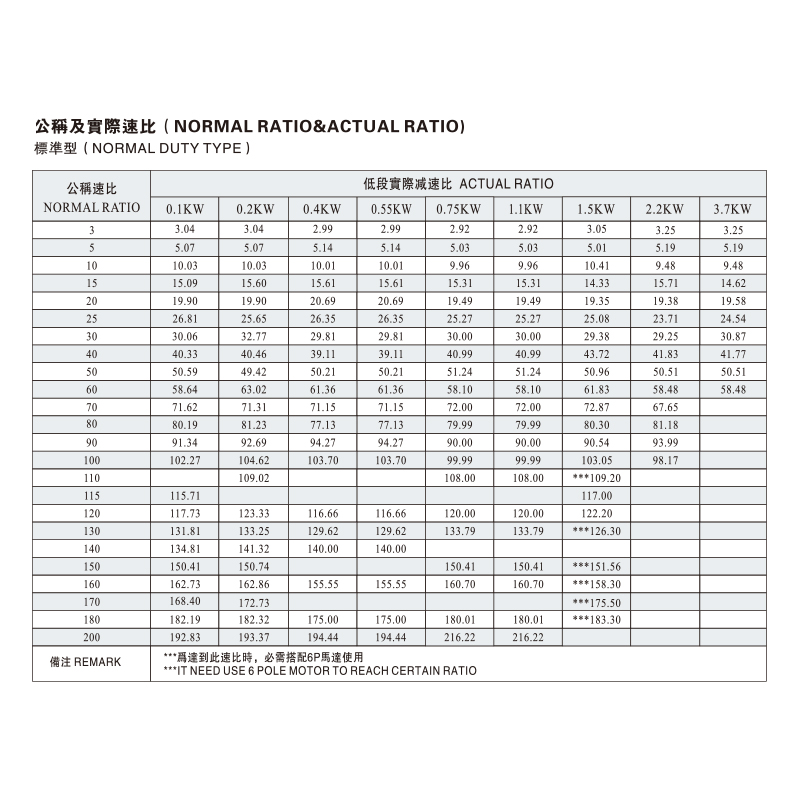

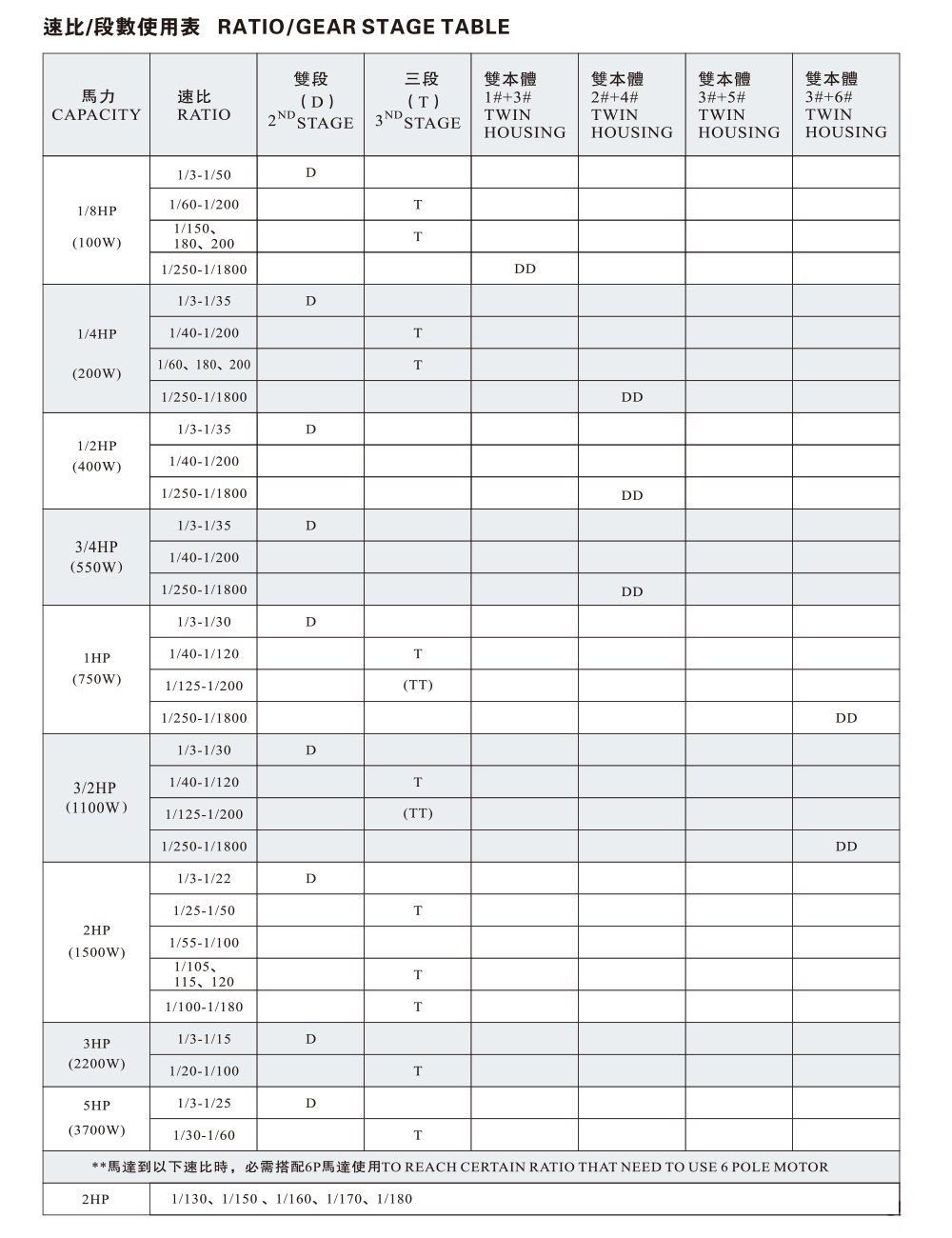

Another frequently discussed benefit is flexibility. Gear motors are offered in a wide range of gear ratios, enabling designers to fine-tune speed and torque output for different tasks. This flexibility is often essential in automated production lines that require stable torque at controlled speeds.

Summary of Key Advantages

| Advantage | Description |

|---|---|

| Torque Output | Supports heavy loads and continuous operation |

| Compact Structure | Suitable for machines with limited installation space |

| Energy Efficiency | Reduced energy use when properly matched |

| Ratio Flexibility | Different gear ratios for varied speed/torque needs |

Considerations and Trade-Offs Reported by Engineers and Users

Despite their advantages, High Power Gear Motor solutions require careful evaluation. Users often ask: What specifications matter most for long-term performance? How do environmental conditions affect reliability?

Common considerations:

- Specification matching

Selecting the correct torque rating, speed, gear ratio, and motor size is essential. Over-specifying may lead to unnecessary cost, while under-specifying can shorten product lifespan.

- Maintenance and wear

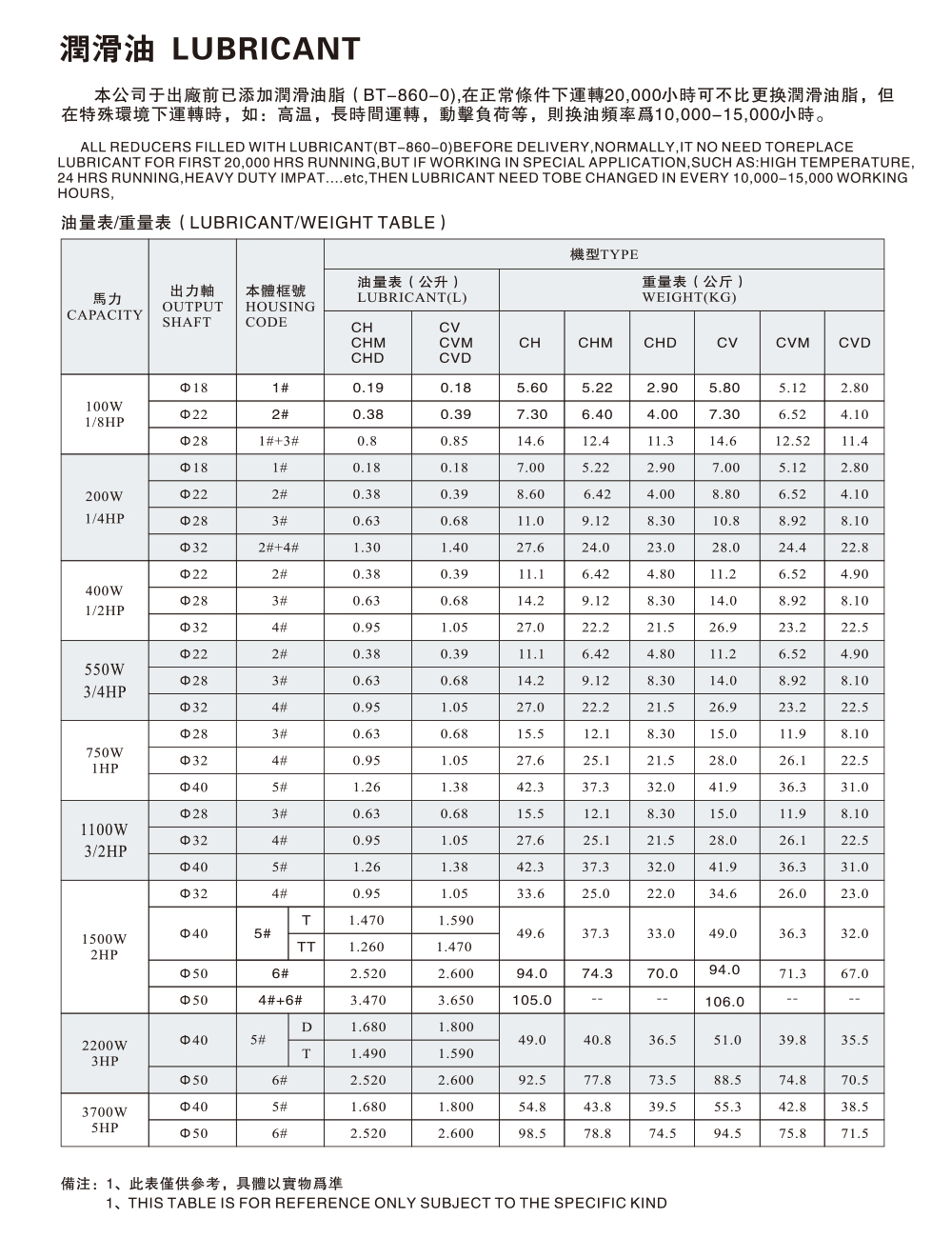

Gear motors may experience gear wear, lubricant degradation, or heat buildup over time. Consistent maintenance supports stable performance and reduces unexpected downtime.

- Cost vs. benefit

Gear motors typically have a higher upfront cost compared with standalone motors. However, the added control and torque output can justify the investment depending on system requirements.

- Application suitability

Not every high-power application requires a gear-reduced system. In some cases, direct-drive solutions are considered when high speed and low torque needs align with equipment design.

These trade-offs reinforce the importance of technical assessment and application-specific evaluation before procurement decisions are made.

Industry Adoption and Outlook

Market activity shows growing interest from sectors such as:

- Industrial automation

- Packaging and logistics

- Food processing and mixing systems

- Agricultural machinery

- Wastewater treatment equipment

Demand is shaped by production efficiency strategies, space-optimized machinery design, and the need for reliable mechanical power transmission in continuous-operation environments.

Looking ahead, companies may focus on evaluating motor-gearbox integration, lifecycle expectations, and opportunities to standardize components across different equipment models. These considerations help ensure that the High Power Gear Motor remains aligned with industry requirements for balanced torque output, adaptable design, and consistent operational performance.

English

English 中文简体

中文简体 عربى

عربى

Contact Us