Practical Applications of Automation Equipment Gear Motors

Automation equipment gear motors are essential components in modern machinery that require precise motion control and reliable torque. By combining an electric motor with a gearbox, these devices deliver specific speed and torque outputs suitable for automated systems, robotics, and precision equipment. ZP Gear Motor offers a range of AC gear motors, DC brushless gear motors, and compact gear units for different industrial applications.

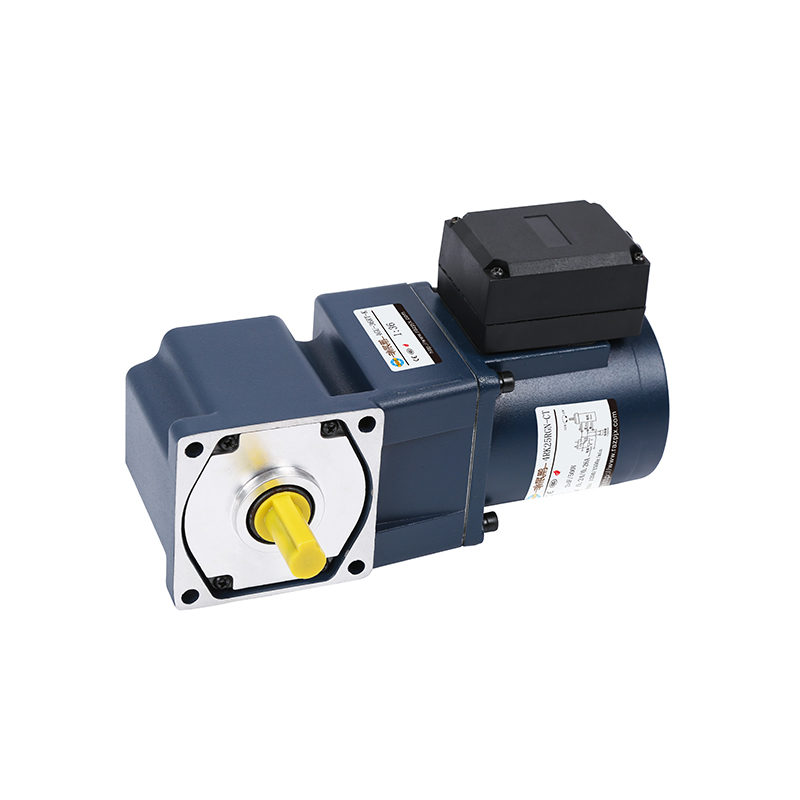

A key feature of these gear motors is their energy-efficient performance. Gearboxes with carefully arranged gears and low-friction transmission reduce energy losses during operation. Helical and planetary gear arrangements lower vibration and mechanical noise while providing consistent torque. For example, an inline AC gear motor rated at 90 W to 120 W can deliver torque around 6700 gf·cm at speeds near 1350 r/min, supporting smooth operation in conveyor systems and automated assembly equipment.

Compact gear motors are particularly suitable for space-limited applications. Small AC gear units or DC brushless gear motors with housing diameters between 60 mm and 100 mm can be integrated into robotic arms, laboratory automation, or precision feeders without occupying excessive space. Despite their compact size, these motors maintain sufficient torque for accurate positioning and motion control. Worm and bevel gear configurations are often used to provide higher torque in a small footprint, ensuring reliable operation in restricted areas.

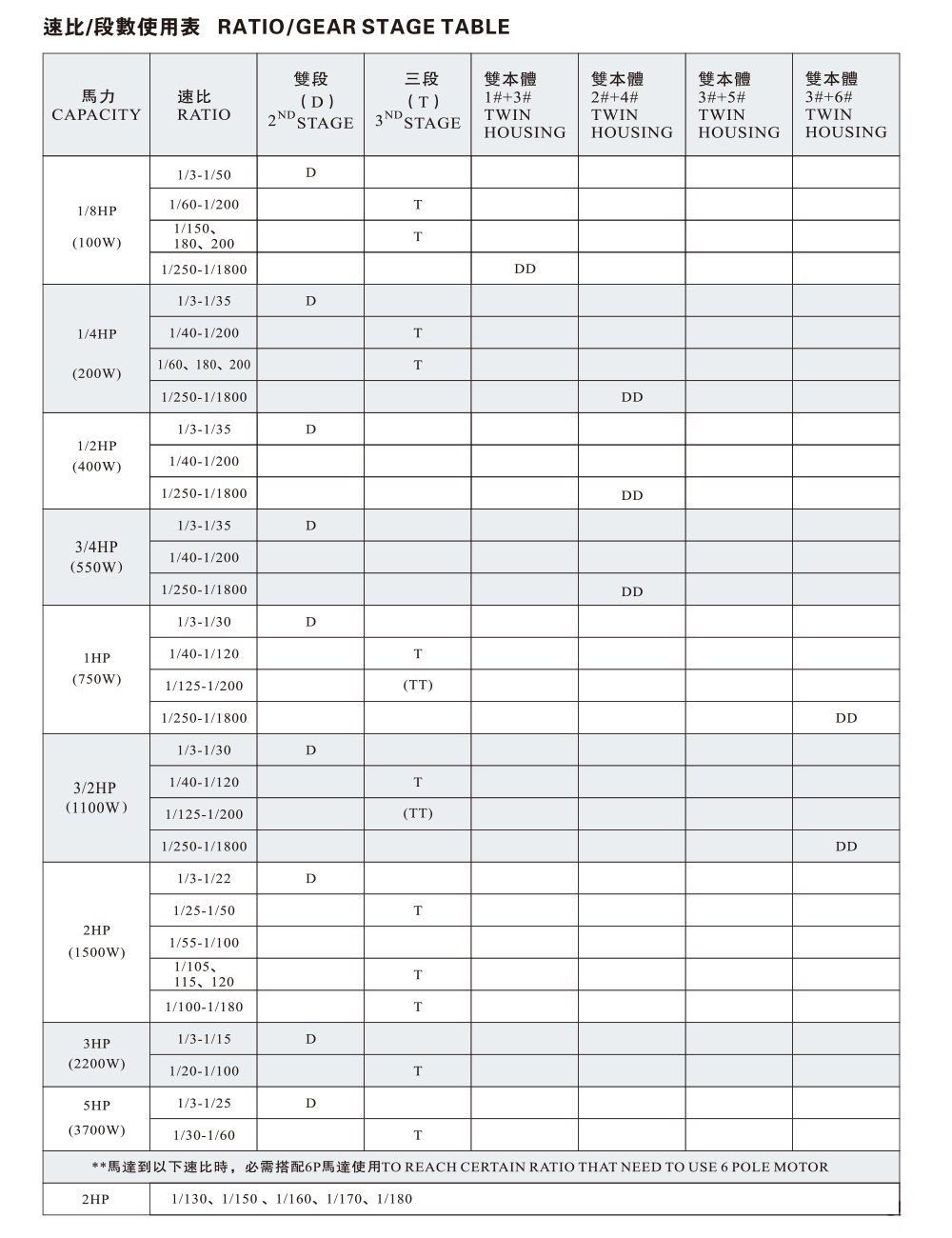

Precise speed and torque control is another important aspect. Planetary and worm gear configurations offer a range of reduction ratios, supporting torque values from under 1 N·m in smaller units up to several newton‑meters in larger brushless motors. This allows machinery to operate reliably under varying loads, whether moving light materials on a conveyor or performing delicate assembly tasks.

Integration with smart monitoring features enhances the functionality of automation gear motors. Embedded sensors can measure rotation, temperature, and vibration in real time. When connected to IoT systems, this data allows remote diagnostics and predictive maintenance, helping prevent unplanned interruptions and maintain continuous operation. Sensor feedback can detect early changes in performance, enabling maintenance to be scheduled before mechanical issues occur.

Automation gear motors are also applied in electric mobility and renewable energy systems. For example, they can drive solar tracking mechanisms, small wind turbines, or components in electric transport devices. Smooth torque output and controlled speed allow these systems to operate with minimal mechanical stress, increasing reliability and lifetime across mechanical assemblies.

FAQ

Q1: What technical role does a gearbox play in a gear motor?

A1: The gearbox reduces motor speed and increases torque, enabling precise motion control tailored to machinery requirements.

Q2: How do compact gear motors support space-limited applications?

A2: Small gear motor designs feature compact housings with different mounting options, fitting into restricted areas while maintaining sufficient torque for accurate motion.

Q3: What types of gear configurations are commonly used?

A3: Planetary, worm, and helical gear arrangements provide different torque and speed characteristics suited to specific tasks.

Q4: How does sensor integration improve gear motor performance?

A4: Sensors provide real-time operational data, allowing remote diagnostics, preventive maintenance planning, and early detection of irregular operation.

Automation equipment gear motors provide reliable motion control, energy-efficient operation, and advanced monitoring capabilities. Their technical configurations and diverse power options make them suitable for a wide range of automation systems, from compact robotics to continuous-production machinery.

English

English 中文简体

中文简体 عربى

عربى

Contact Us