Parallel Shaft Gear Motors in Industrial Applications

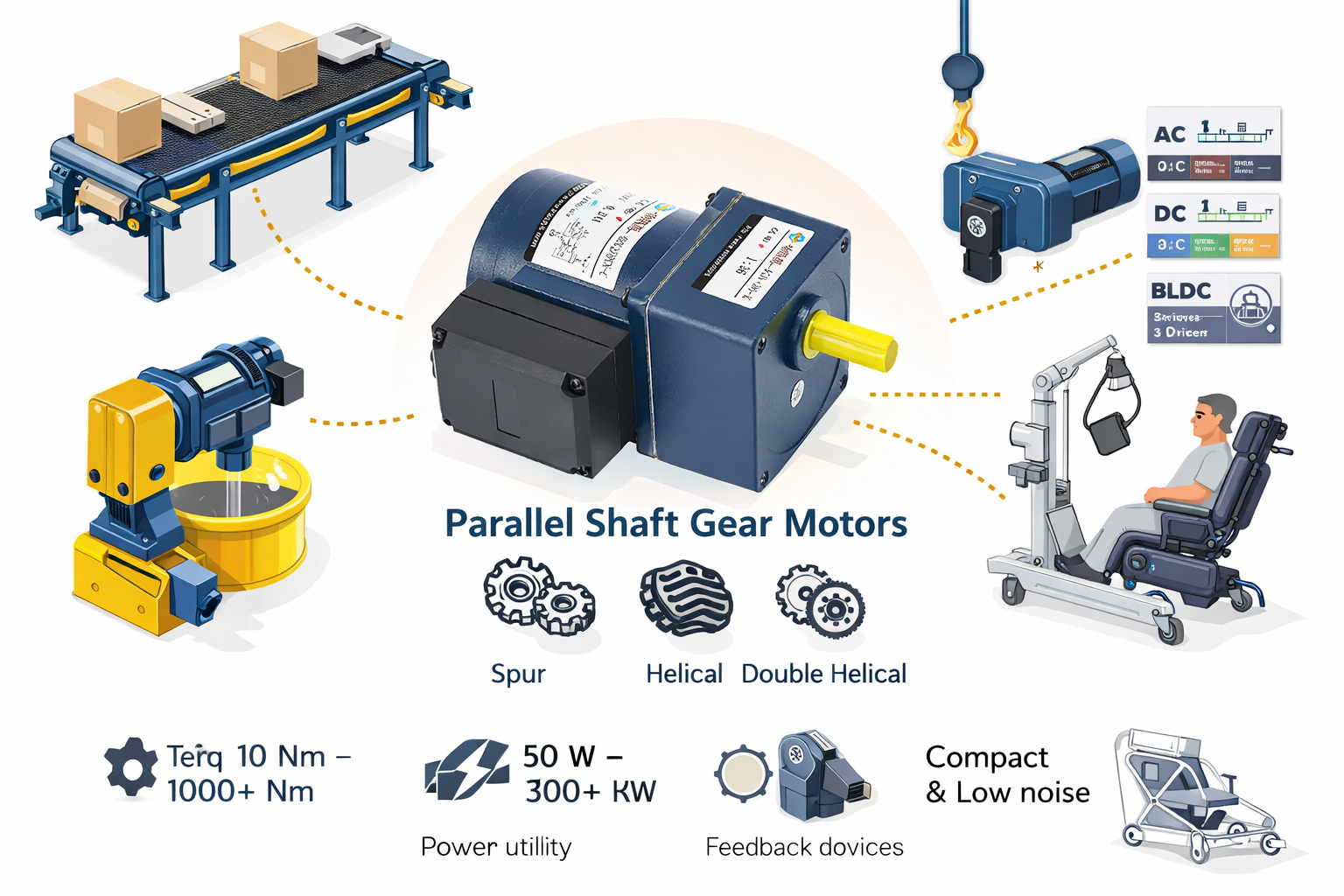

Gear Motor Parallel Shaft are increasingly recognized for their versatility in industrial and medical equipment. Their design, featuring an output shaft parallel to the motor shaft, enables efficient power transmission across a wide range of machinery. Commonly, these motors are found in conveyors, material handling systems, mixers, and lifting devices, providing reliable and continuous motion for various operations.

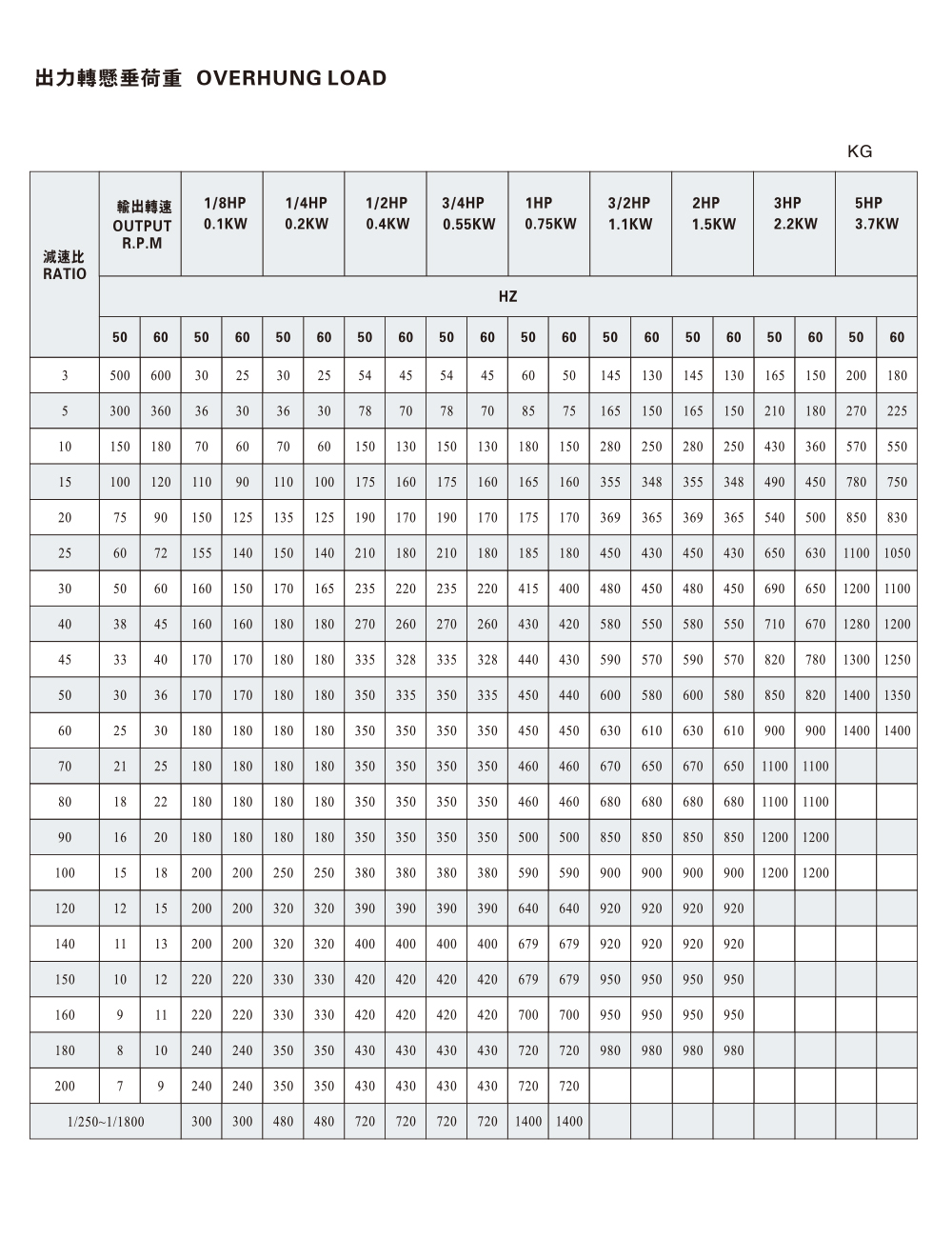

One significant advantage of parallel shaft gear motors is their ability to handle different load requirements while maintaining smooth performance. For instance, small parallel shaft gear motors are suitable for OEM equipment, compact transport systems, and medical lifting devices such as patient lifts and adjustable wheelchairs. In industrial settings, larger motors can deliver torque ranging from tens of newton-meters to several thousand newton-meters, with power ratings spanning from tens of watts to several hundred kilowatts, accommodating both light and heavy-duty applications.

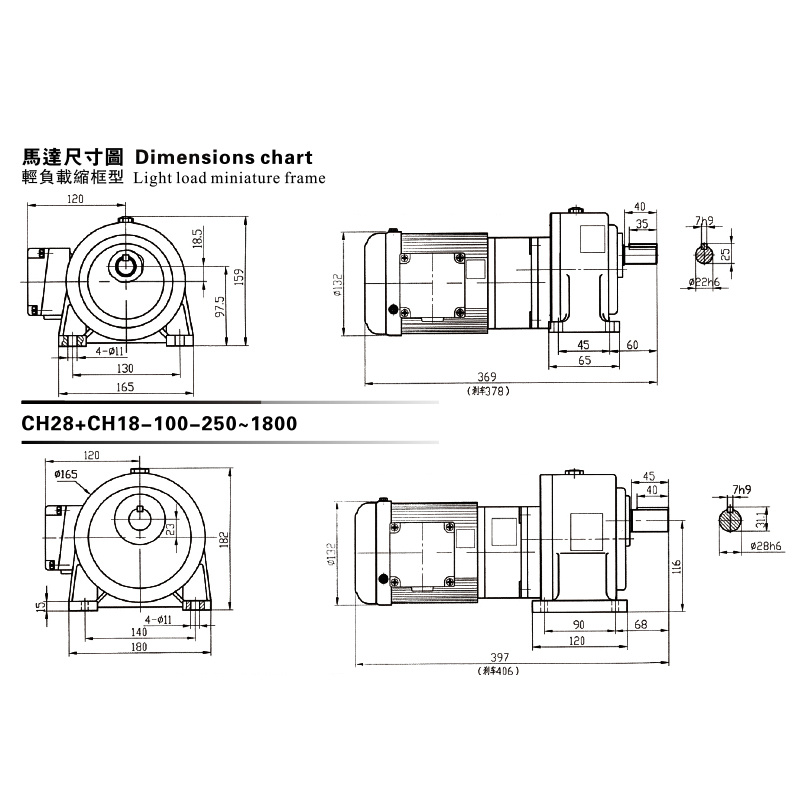

The structural design of these motors supports both durability and operational efficiency. Internal gearing options include spur, helical, and double helical gears, allowing for low-noise and low-vibration operation. Helical gear profiles, in particular, distribute load across the gear teeth, improving transmission stability and extending service life. Standard parallel shaft gear motors also offer diverse mounting options, including foot-mounted, flange-mounted, and shaft-mounted configurations, making them adaptable to various equipment layouts.

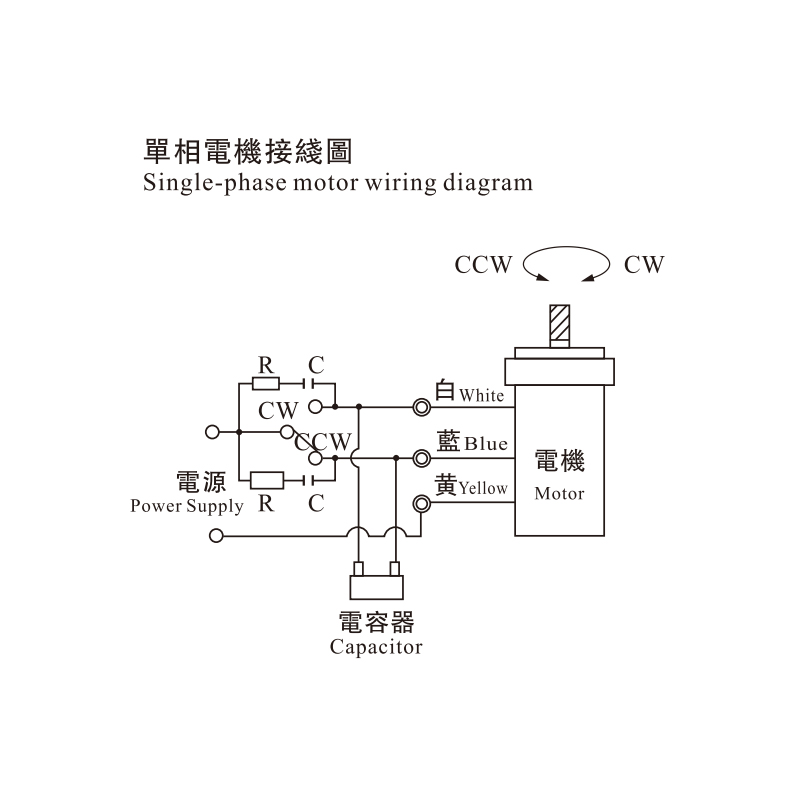

Performance benefits extend beyond mechanical stability. Parallel shaft configurations generally offer higher transmission efficiency compared to right-angle gear designs. Compact and lightweight, they fit well in machinery with limited space. Certain models are equipped with sealed housings, suitable for mildly dusty or humid environments, ensuring reliability in challenging conditions. Additionally, the motors can be paired with AC, DC, or brushless DC (BLDC) drives, and integrated with speed feedback devices or encoders to enable closed-loop control.

Recent industry discussions highlight the importance of selecting the right motor specifications and ensuring precise installation for optimal performance. Engineers stress that careful load matching and accurate shaft alignment not only extend the motor’s lifespan but also reduce operational vibration and mechanical wear.

In practical applications such as mixers, low-speed conveyors, and automated material handling equipment, these motors deliver steady and reliable motion over extended periods. Their ability to sustain continuous operation with fluctuation in speed or torque contributes to higher process efficiency and reduces the risk of mechanical downtime. Additionally, proper integration with feedback devices or control systems further enhances performance by allowing real-time monitoring and adjustments, ensuring that production or operational tasks proceed smoothly and safely.

Frequently Asked Questions

Q1: What types of gears are used in parallel shaft gear motors?

A1: Common gear types include spur, helical, and double helical gears, chosen based on load, noise, and efficiency requirements.

Q2: Can these motors be used in medical lifting devices?

A2: Yes, small parallel shaft gear motors are often used in patient lifts, adjustable wheelchairs, and other medical equipment.

Q3: How can performance be optimized?

A3: Ensuring correct shaft alignment, selecting the appropriate gear ratio, and integrating feedback devices can improve efficiency and reduce wear.

Q4: What installation options are available?

A4: Standard configurations include foot-mounted, flange-mounted, and shaft-mounted options to fit diverse machinery layouts.

Gear Motor Parallel Shaft provide a flexible, efficient, and reliable solution for various industrial and medical applications. Their combination of customizable design, stable transmission, and compact form makes them a practical choice for engineers and manufacturers aiming for long-lasting performance.

English

English 中文简体

中文简体 عربى

عربى

Contact Us