The Essential Role of Gear Boxes in Modern Machinery

In the intricate world of mechanical engineering, the gear box stands as a fundamental component that plays a crucial role in the functionality and efficiency of various machines and vehicles. Whether in automobiles, industrial equipment, or renewable energy systems, gear boxes are indispensable for transmitting power and controlling speed. This article explores the importance, functionality, and applications of gear boxes, highlighting their significance in modern technology.

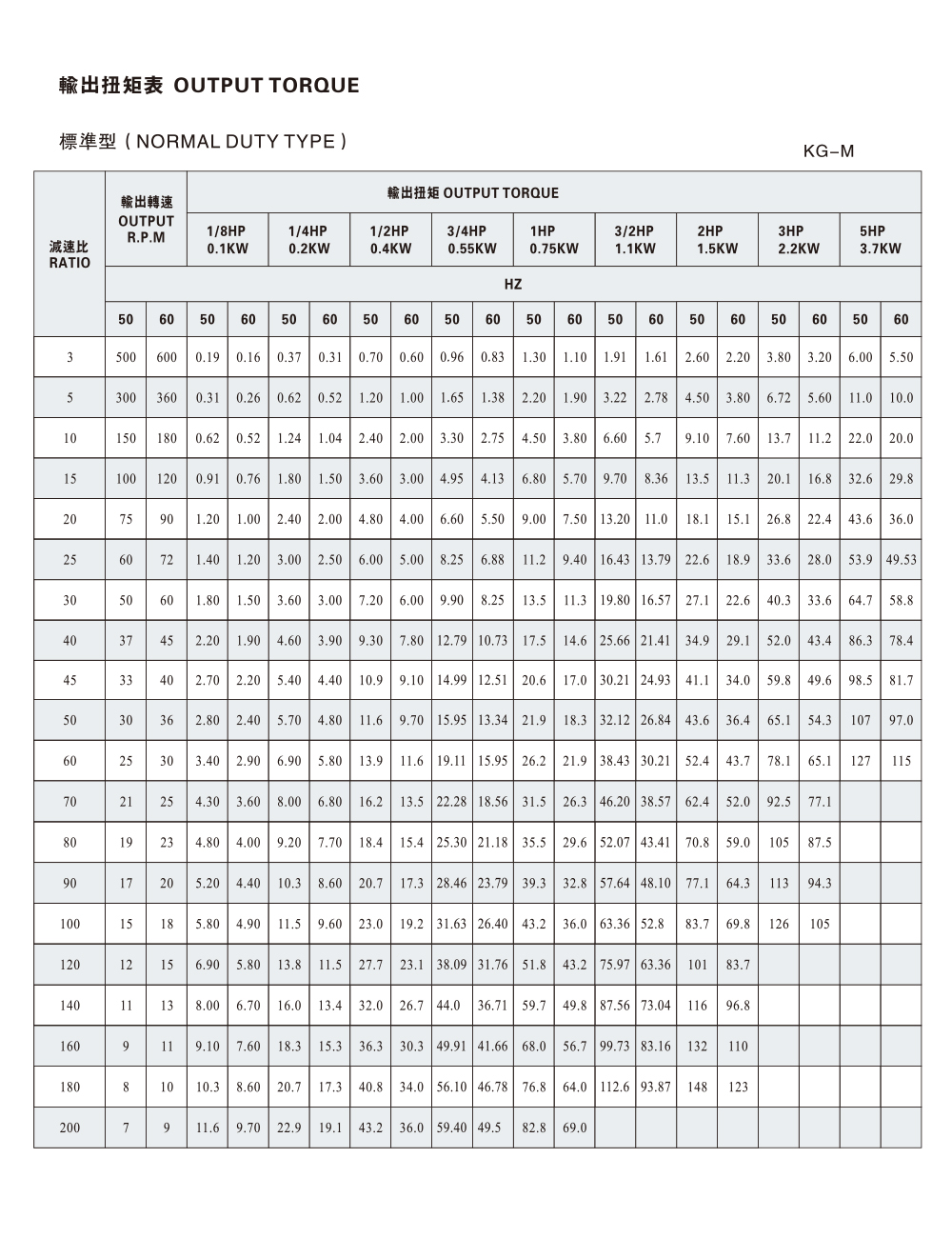

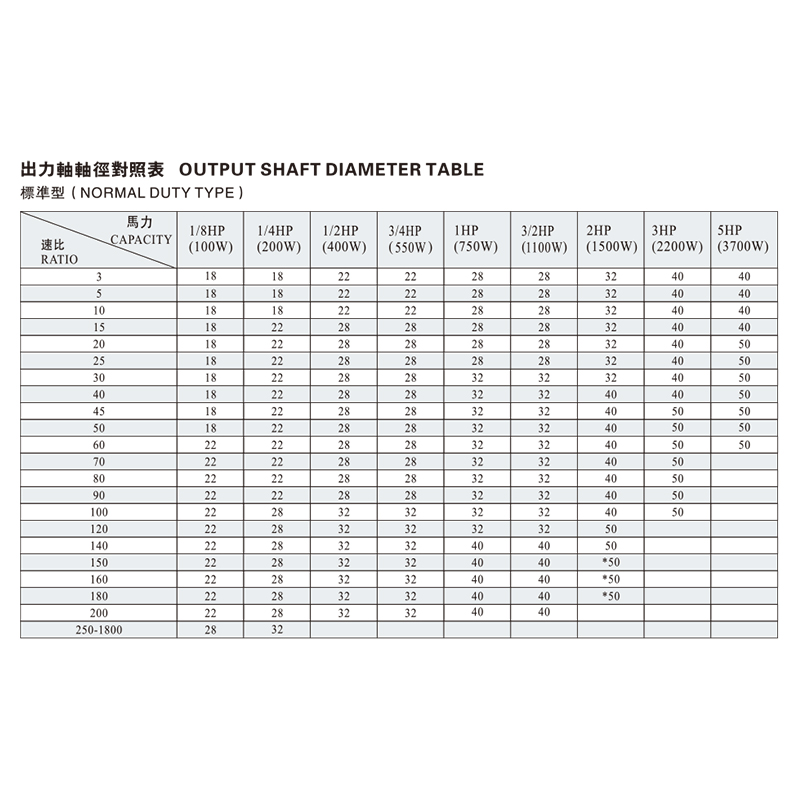

A gear box is a mechanical device that uses a set of gears to transmit power from one shaft to another while changing the speed and torque. The primary function of a gear box is to convert the high-speed, low-torque output of a motor or engine into a lower-speed, higher-torque output that is more suitable for driving various mechanical systems. This conversion is essential for optimizing the performance and efficiency of machines.

The operation of a gear box relies on the interaction of different types of gears, such as spur gears, helical gears, and bevel gears. Each type of gear has specific characteristics that make it suitable for particular applications. For example, spur gears are simple and efficient for applications requiring high torque transmission, while helical gears offer smoother operation and can handle higher loads.

The gear ratio, which is the ratio of the number of teeth on the output gear to the number of teeth on the input gear, determines the speed and torque conversion. A higher gear ratio results in a greater reduction in speed and an increase in torque, making it possible to drive heavy loads at lower speeds.

Gear boxes are used in a wide range of applications across various industries. In the automotive sector, they are integral to the transmission systems of cars, trucks, and motorcycles. They allow drivers to select different gear ratios to match the driving conditions, providing optimal performance and fuel efficiency. Without gear boxes, vehicles would struggle to accelerate or climb hills efficiently.

In industrial settings, gear boxes are used in conveyor systems, pumps, and fans to control the speed and torque of the machinery. They ensure that the equipment operates at the desired speed, enhancing productivity and reducing wear and tear on the components.

Renewable energy systems, such as wind turbines, also rely on gear boxes to convert the rotational speed of the turbine blades into a higher speed suitable for driving the generator. This conversion is critical for maximizing the efficiency of power generation and ensuring a stable output.

The proper maintenance of gear boxes is essential for their longevity and performance. Regular inspections, lubrication, and replacement of worn components can significantly extend the life of a gear box. Over time, gears can wear out, and bearings can become misaligned, leading to reduced efficiency and potential failure. By following recommended maintenance schedules, users can ensure that their gear boxes continue to operate reliably and efficiently.

Advancements in materials and manufacturing techniques have led to the development of more efficient and durable gear boxes. High-strength alloys and advanced lubricants have improved the performance and lifespan of gears, while computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies have enabled the production of more precise and complex gear designs.

In recent years, there has been a growing focus on developing gear boxes that are more energy-efficient and environmentally friendly. This includes the use of lightweight materials and the integration of smart technologies that allow for real-time monitoring and optimization of gear box performance.

Gear boxes are a vital component in modern machinery, providing the essential function of power transmission and speed control. Their versatility and reliability make them indispensable in various applications, from automobiles to industrial equipment and renewable energy systems. By understanding the mechanics of gear boxes and implementing proper maintenance practices, users can ensure that these critical components continue to perform efficiently and effectively. As technology continues to advance, gear boxes will undoubtedly play an even more significant role in the development of innovative and sustainable mechanical systems.

English

English 中文简体

中文简体 عربى

عربى

Contact Us