Custom Gear Motor Powers the Next Wave of Intelligent Motion Systems

In modern automation, Custom Gear Motor has become more than a simple mechanical component. It now represents a bridge between design flexibility, precision motion, and digital innovation.

Custom Gear Motor and the Rise of Smart Manufacturing

Smart manufacturing transforms how machines move and interact. Every motion component must respond quickly and accurately under data-driven control. Custom gear motors enable this transformation by aligning torque, speed, and structure to unique system requirements. Their role extends beyond mechanical output—these motors support integrated control, easy maintenance, and flexible adaptation across diverse production lines.

Manufacturers now rely on custom gear motors to reduce downtime and enhance synchronization across automated stations. This precision in movement helps achieve smoother transitions between processes and improves the overall efficiency of digital production environments.

Custom Gear Motor Sustainability and Energy Efficiency Focus

Sustainability has entered the core design philosophy of motion systems. Custom gear motors are increasingly developed using recyclable materials and optimized structures that minimize energy loss. Engineers design them to maintain stable torque at lower current loads, reducing electricity consumption over time.

Energy-efficient gear motors contribute directly to the environmental goals of modern factories. They also help companies lower operational costs without sacrificing performance or durability. The use of lightweight housings and improved heat management ensures longer service life while maintaining mechanical integrity.

Custom Gear Motor Lightweight and Compact Design Trend

The movement toward smaller and more efficient machinery continues to reshape gear motor engineering. Compact designs that deliver higher torque density now dominate new product lines. Custom gear motors combine strong power output with reduced size, allowing installation in limited spaces while maintaining stable operation.

This trend benefits mobile robotics, drones, and automated laboratory systems. In packaging and assembly lines, smaller motors free up room for additional components, helping engineers create more efficient layouts. Lightweight design also reduces overall equipment weight, improving system responsiveness and transport convenience.

Custom Gear Motor Digital Configuration

Digital configuration platforms have revolutionized customization. Engineers can now specify torque ranges, ratios, or mounting types through intelligent design interfaces. These digital tools shorten the development cycle and minimize design errors through real-time simulation.

Custom Gear Motor Applications Across Key Industries

Every industry presents unique challenges that standard motors cannot always address.

In robotics, custom gear motors handle flexible axis control, reduce backlash, and maintain consistent torque in repetitive movement.

In agriculture, corrosion-resistant models perform under outdoor conditions, managing irrigation and harvesting devices effectively.

In packaging machinery, custom gear motors maintain synchronized movement for precise product handling.

Custom Gear Motor Market Opportunities

Integration of sensors, feedback modules, and advanced control electronics transforms traditional gear units into intelligent motion modules. The future of customization lies in adaptive design—gear motors that not only move machines but also gather data, support analytics, and enhance system intelligence.

Product Recommendation

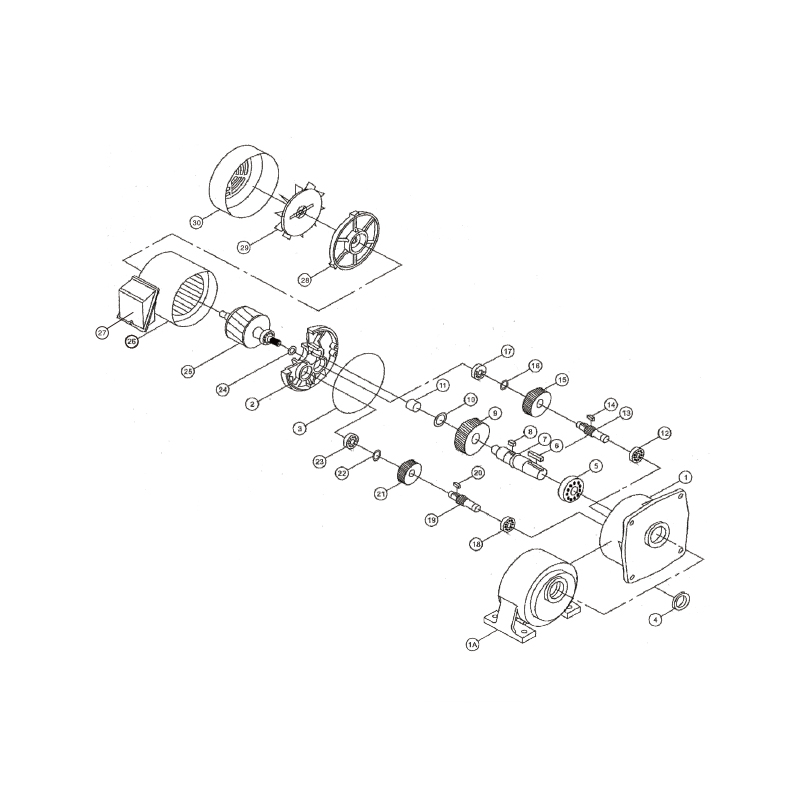

Across robotics, medical equipment, and automation systems, Custom Gear Motor has become a foundation for precision and reliability. Its flexibility, efficiency, and innovative features position it as a central part of modern mechanical engineering. For operations that require dependable torque, compact structure, and accurate control, the 100mm 160W/180W High Precision Gear Reducer Motor delivers balanced performance and long-term stability.

For more detailed product information, please consult Zhanpeng Company.

English

English 中文简体

中文简体 عربى

عربى

Contact Us