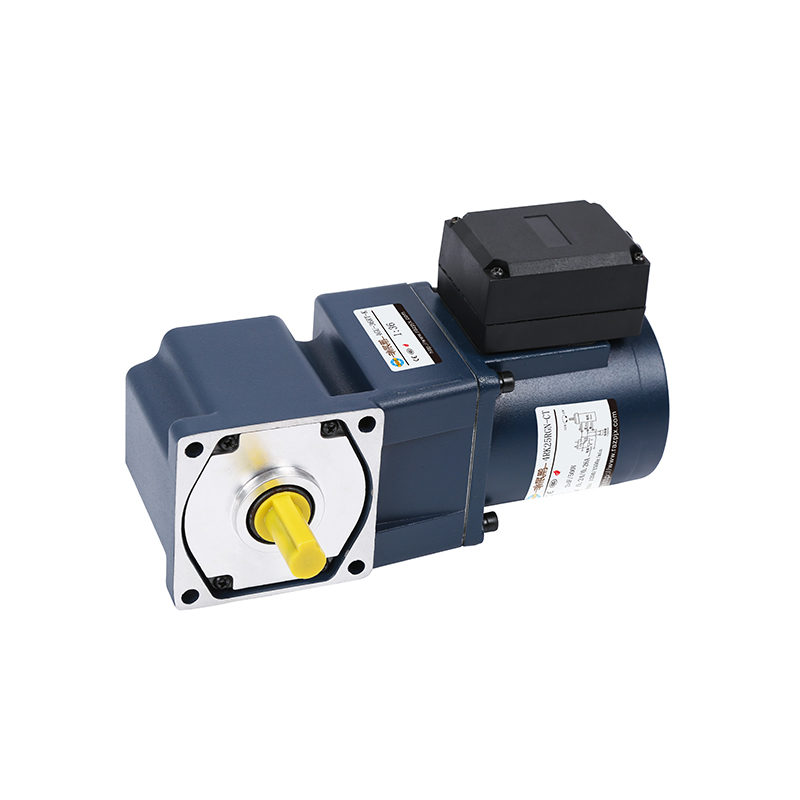

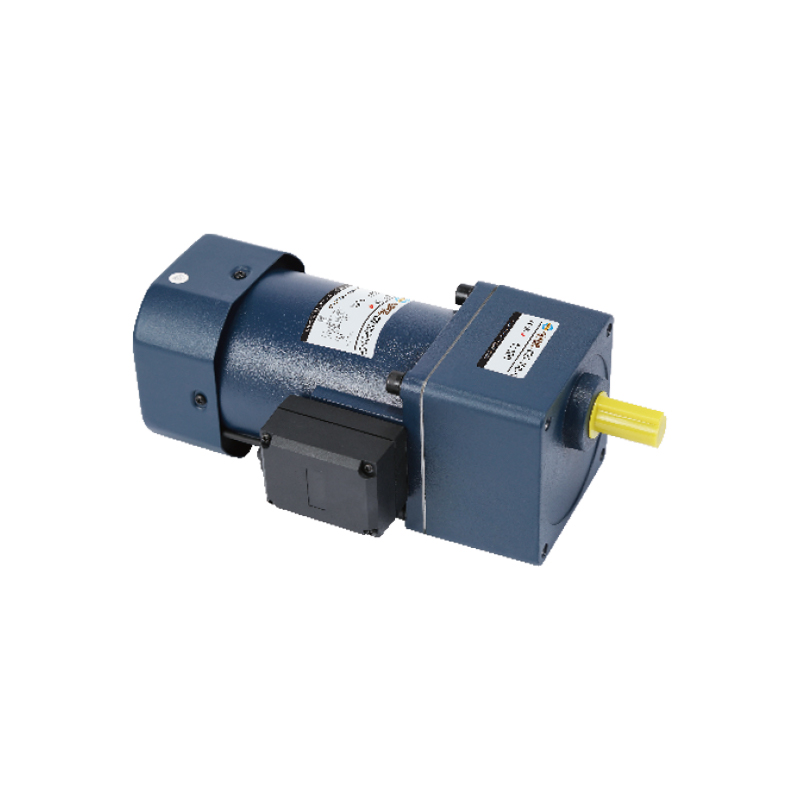

Vertical Angle Motor Expands Applications in Printing and Industrial Equipment

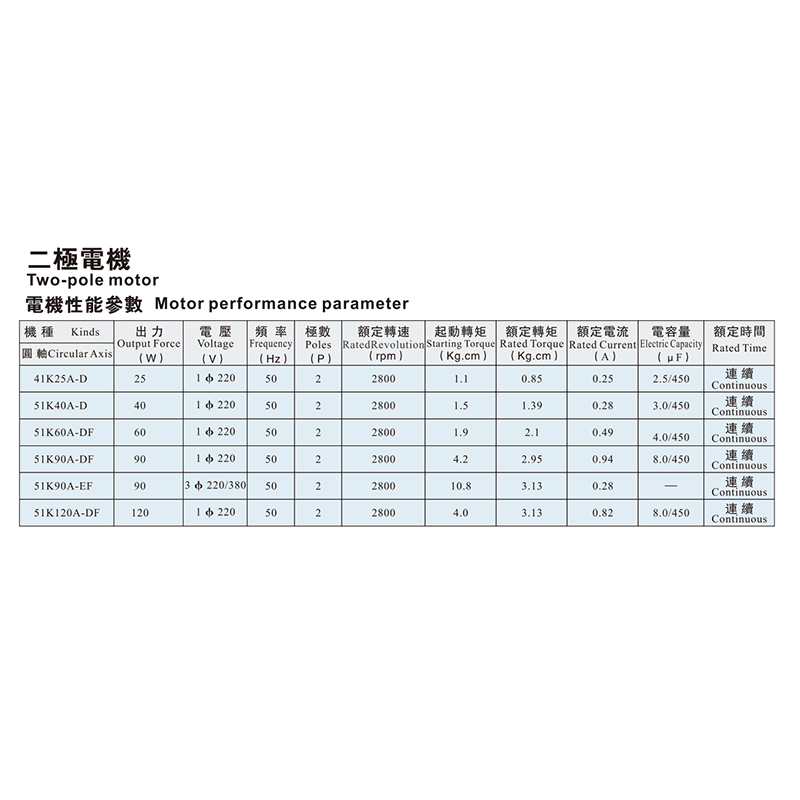

The introduction of Vertical Angle Motor technology has added a new dimension to modern machinery design, offering reliable performance across industries such as printing, packaging, and precision equipment. These motors are increasingly applied in systems that require controlled torque, compact structures, and smooth integration with other components. Their adaptability has led to growing use in flexo printing machine setups, CI flexo printing machine systems, and in combination with micro motor units, gearboxes, and reducers.

In printing applications, the role of the Vertical Angle Motor is particularly important. Flexo printing machines rely on accurate speed control and steady operation to maintain print quality across long production runs. The result is more consistent output, which supports the needs of packaging, labeling, and flexible material printing. Similarly, in CI flexo printing machines, where multiple colors are applied in precise alignment, Vertical Angle Motors help reduce vibration and maintain accurate registration. This ensures stable performance across varying production requirements.

The synergy between Vertical Angle Motors and micro motors also reflects advances in compact mechanical engineering. Micro motors are often used for auxiliary functions such as tension control or small-scale adjustments within larger machines. This layered approach ensures that complex machinery, from printing presses to specialized production equipment, can operate efficiently without unnecessary strain on individual components.

Another key aspect of Vertical Angle Motor integration is the use of gear boxes. Gear boxes act as intermediaries that translate the motor’s rotation into practical mechanical output for specific tasks. When paired with Vertical Angle Motors, gear boxes enable more versatile speed and torque management, making machines suitable for different types of materials and production speeds. In printing equipment, this allows operators to adapt machines for thin films, paper, or cardboard with minimal reconfiguration. The controlled interaction between motor and gear box highlights the importance of mechanical harmony in industrial design.

The role of reducers is equally significant in the broader application of Vertical Angle Motors. A reducer moderates motor speed while amplifying torque, which is critical for applications that demand strength and endurance. In flexo and CI flexo printing machines, reducers help balance motor efficiency with the mechanical load required by rollers and print cylinders. The integration of Vertical Angle Motors with reducers also supports energy efficiency, a growing priority in industrial operations.

Beyond printing, Vertical Angle Motors demonstrate potential in wider industrial and commercial applications. They provide reliable solutions for equipment that requires compact yet durable motor systems, making them suitable for areas such as material handling, packaging machinery, and specialized automation. When combined with gear boxes and reducers, they deliver adaptable performance that meets diverse operational requirements without excessive energy consumption or structural bulk.

The growing use of Vertical Angle Motors underscores how motor technology interacts with other essential machine parts to form integrated systems. Flexo printing machines depend on coordinated motor performance for print quality, CI flexo printing machines rely on stability for accurate color alignment, micro motors enhance precision, and gear boxes and reducers ensure torque management and energy balance.

Looking forward, Vertical Angle Motors are expected to remain an important factor in the design of printing and industrial equipment. Their ability to adapt to complex machinery, provide stable output, and integrate with supporting components ensures they will continue to serve vital roles across production environments.

English

English 中文简体

中文简体 عربى

عربى

Contact Us